Tutorials

WATCH OUR STONE AND BRICK VENEER TUTORIAL VIDEOS

Properly installing veneer stone is the most important step in creating a long-lasting, believable space. Our installation guidelines walk through the process step-by-step to ensure your stone will last the test of time. Learn how to install manufactured stone with detailed videos and clear instructions. Install stone veneer and brick with ease.

Step By Step Instructions

Step By Step Instructions

DOWNLOAD our stone estimation guide to make sure you purchase the right amount for your project.

STONE GROUTING TECHNIQUES

Grout (and sometimes the lack of grout) has an amazing impact on the look and authenticity of stonework. Selecting the desired grout technique and grout color is often as important as selecting the stone. Here we will expore expert stone grout techniques that can be used in a variety of stone projects. Whether you call it thin stone veneer, faux stone veneer or artificial stone veneer, it always benefits from grout. There are three distinct stone grout techniques: Dry- Stack Joints, Standard Joints (Raked) and Overgrout Joints.

Dry-Stack Joint

Standard Joint

Overgrout Joint

DOWNLOADS & RESOURCES

From technical information about our stone and brick veneer products to warranties and maintenance, we’ve got you covered with the resources you need. If you can’t find the information you are looking for, feel free to give us a call!

Technical Specifications

Splitting Tensile Strength: 590 psi

Absorption: 13.3% increase in weight of stone if submerged in water.

Thermal Resistance: R = .60

Shear Strength: 115 psi

Fire Rating:

UL classification shows zero flame spread, zero fuel contributed, and zero smoke developed.

Durability:

Numerous installations in Alaska, Canada, and Northern United States are successful tests in themselves of the durability and freeze/thaw resistance of Eldorado Stone.

Repetition:

Eldorado Stone is manufactured from thousands of different molds and each stone is individually colored, so the chances of repetition on any surface are negligible.

Dimensions:

Eldorado Stone varies in thickness from ¾ inch to 3½ inches, and in size from 8 square inches to 4 square feet, all dependant on stone style.

Color Retention:

Only permanent mineral oxide colors are used. No detectable color change can be observed even after years of weathering.

**Detailed technical data is available upon request.

Installation and Mainenance

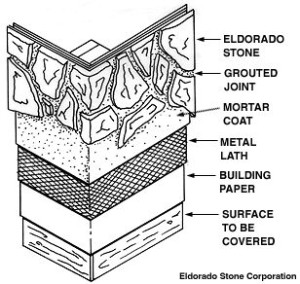

Manufactured stone is commonly installed over four basic substrates:

Concrete Masonry Block | Sheathing | Rigid Insulation | Open Stud Framing

These substrates form the basis for our basic installation instructions.

Surface Preparation:

Manufactured stone can be applied to any structurally sound surface. Due to its light weight nature, no special foundations or structural alterations are necessary.

On clean (unpainted, untreated and unsealed) brick, block, concrete or other masonry surfaces, install manufactured stone directly to the surface.

On all other surfaces, metal lath must be applied first. Outside, on wood surfaces, apply a vapor barrier such as felt building paper before attaching the lath.

Scratch Coat:

Although many installations may not require a scratch coat, as a rule all lathed surfaces should be covered with a thin coat of mortar (scratch coat) and allowed to set prior to installing manufactured stone.

Applying the Stone:

Stones are applied with mortar in random patterns with uniform joints similar to the setting of real stone. The stones can be cut and trimmed with a hatchet, brick trowel or nippers.

Grouting the Joints:

The joints are filled with selected grout, then tooled and brushed to simulate real stone applications.

Sealing:

The use of a high quality waterproofing sealer such as Craftshield is desirable on any manufactured stone surface, but especially on those exposed to severe freezing and thawing, excessive moisture, or conditions which could discolor or stain the stone. The use of a sealer reduces the absorption percentage from 13.3% down to 4%.

Maintenance:

No special maintenance is required. If surface soiling occurs, the pressure of water from a garden hose will usually be effective in cleaning the stone veneer.

CAUTION: Do not use acid in an attempt to clean the stone.

Download the National Concrete Masonry Association Install Guidelines HERE.

If you’ve got a question, we’ve got an answer!

Q. What is manufactured stone made from?

Q. How heavy is manufactured stone?

Q. How thick is a piece of manufactured stone?

Q. Is there a warranty on manufactured stone?

Q. How are the colors applied to the stone?

Q. Will the stone fade over time?

Q. Is manufactured stone cheaper than natural stone?

A. Yes, installing manufactured stone is typically less expensive than installing natural stone. This is because it is light weight and does not require any footings, foundation, or wall ties. This also reduces the installation time and has a 2% waste factor vs. 10% or more for natural stone.

Q. What kind of surface do you apply manufactured stone to?

Q. Can manufactured stone be used around swimming pools?

Q. Are there any water issues?

Q. Can manufactured stone be used as a flooring?

Q. Can manufactured stone stain?

Q. Are the stone colors on this webpage accurate?

Q. What is the installed price of manufactured stone?

A. The installed price is approximately $20.00 – $50.00 per square foot based on many factors including brand of stone, style of stone chosen, installation technique, location of the job, interior vs exterior application, and many other jobsite variables.